All about your K9 Series Subwoofers:

Wiring for 1 DVC 2 Ohm SUBS:

Wiring for 2 DVC 2 Ohm SUBS:

Description:

The Rockville K9 series has been our best selling series of subs and it just got even better! Say hello to the K9 V3. This sub is a game changer. We improved the performance and cooling like crazy! Our engineers did some minor tweaks that give major results for bassheads who like to abuse subs! Weather you are an every day user or someone who pushes the limits of your equipment the K9 V3 is for you!

We made the following upgrades that will keep the voice coil cooler improving the subs ability to take constant abuse.

1. The dustcap was upgraded to the same one we use in our Punisher series. It is top of the line. We figured it just cost us a couple dollars extra, so why not throw on the best dustcap.

2. We added an inner dustcap that stops heat from building up in the voice coil. We also made our pole vent smaller. The combination of these 2 changes keeps the voice coil significantly cooler when you are playing bass heavy songs or test tones.3. We added a voice coil spacer that vastly improves the performance.

4. The cone has a smooth finish that allows the dustcap to be glued on more securely.

Features:

- Rockville W10K9D2 V3 K9 Series 10" Dual 2-Ohm Car Subwoofer

- Peak Power Handling: 3200 Watts

- Program Power Handling: 1600 Watts

- RMS Power Handling: 800 Watts

- Ultra-stiff Non-Pressed Paper Punisher Cone

- Ultra-stiff Polypropylene Punisher Dustcap (The K9 V3 now uses the same dustcap as our Punisher series)

- We added an inner dustcap which helps to avoid hot air build-up in the voice coils resulting in more power handling

- More efficient air ventilation cools the voice coil even better than our V2

- We added a voice coil spacer improving longevity during test tones or extreme bass-heavy songs

- 3" 4-Layer Black Aluminum Former Wound with OFC Wire Made in USA

- This voice coil is stable up to 240 degrees celcius! The voice coil windings are made in the USA

- Double Stacked 185 Oz High Quality Magnet

- Cast Aluminum Basket With Black Sanded Finish Makes This Sub Very Efficient And Lighter Weight

- Two Chrome-Plated Binding Post Terminals

- Thick Foam Surround Provides Incredible Sound Quality With Minimal Distortion

- White Stitching Cone Reinforcement Ensures Long Life

- Impedance: Dual 2-Ohm Voice Coils

- Special Custom Rubber Boot Magnet Covers Make the Woofer Look Nice and Protects the Magnet

- Custom Rockville Mounting Gasket Looks Beautiful and Makes it Easy To Mount the Subwoofer Air-Tight

- High BL Magnetic Motor Gap

- We use high grade glue that handles extremely high temperatures which allows our woofer to handle even more power than they are rated

- Nomex Spider provides tear resistance, strength and long-term reliability over regular cotton and poly cotton spiders

- Cutout Diameter: 9.37” inches

- Mounting Depth: 6.5” inches

- Frequency Response: 37.8 Hz - 1.5K kHz

- 10mm T-Yoke + 10mm Washer

- Sensitivity: 85dB

- Sealed Enclosure Volume: 0.55 – 0.95 Cubic Feet

- Vented/Ported Enclosure Volume: 1.2 – 1.8 Cubic Feet

- Xmax is 27MM

- Weight: 29.75 Lbs.

- Shipping Weight: 31.95 Lbs.

- Shipping Box Dimensions: 13.38" x 12.2" x 13.38" Inches

- XMAX: 26 MM

Detailed Info:

- Body: Non-Pressed Paper

- Gap Plate Inside Diameter: 95mm (3.54 inches)

- Gap Plate Outside Diameter: 190mm (7.5 inches)

- Gap Plate Thickness: 25mm (1 inch)

- Yoke Outside Diameter: 180mm (7.1 inches)

- Yoke Thickness: 10mm (0.4 inches)

- Yoke Pole Diameter: 75mm (3 inches)

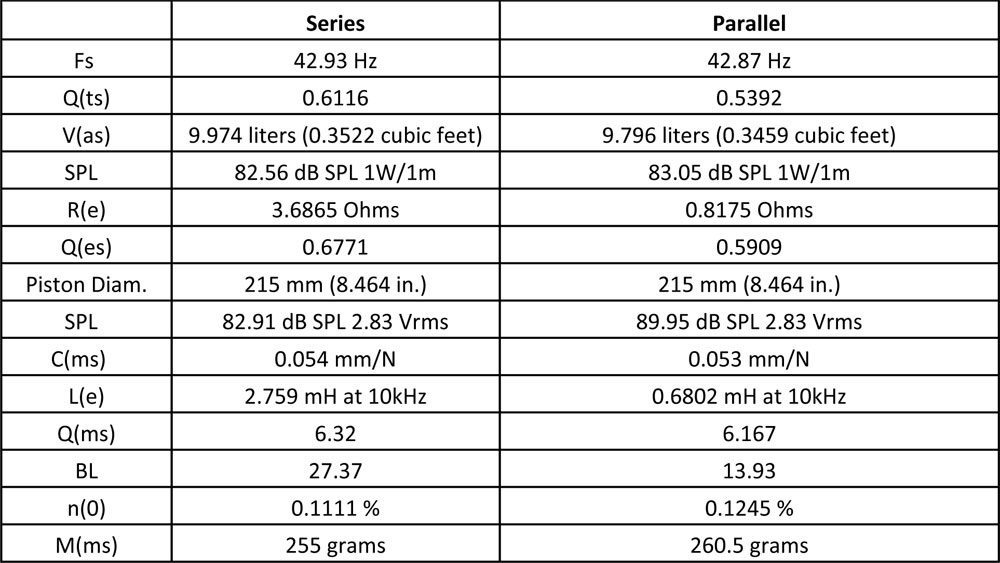

TS Parameters:

About Rockville Quality Control Procedures:

The Rockville brand stands for Quality, Innovation and Value. All Rockville products go through the most rigorous quality control standards in the industry. Products go through months of extensive testing before they reach your hands. All user functions are tested and all internal components are tested for quality. Rockville makes products that are virtually un-breakable! Rockville is one of the only brands in its class to test every concept model for weeks or months before starting production. Once production begins, Rockville sends product engineers to their factory to quality control every line of production. During production every product is tested and on top of that Rockville goes the extra mile and has their high level product engineers do an additional quality control. They test a certain percentage of all products from the production line a second time to ensure that the quality meets their vigorous standards, and to make sure that there is never a batch of products with even a slight problem. All Rockville products are backed with a hassle free warranty, though it is unlikely that you will need to use it.

- UPC:

- 613815773511